CharacteristicsTechnical parametersAchieve effectDimensionProcessOthers

- After blanking, the steel plate does not need to be turned over and can be directly transported into the equipment

- One-time transportation to complete the functions of slag removal and blunting on the upper and lower surfaces of parts

- The double-sided abrasive belt mechanism finishes the upper and lower surfaces of parts

- The double-sided sand block mechanism blunt the upper, lower and inner and outer contours of the parts

- Automatic compensation for abrasive material (optional)

- Process parameters memory

- Servicing intelligence remind

- Abrasive replacement remind (optional)

- Intelligent startup and stop

-

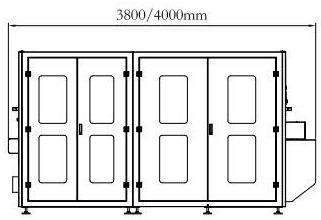

Working width1000mm/1300mm

-

Working thickness5-50mm

-

Conveyor speed0.8-4m/min

-

Slag cleaning speed5-9m/s

-

Belt speed8-20m/s

-

Sand block speed7.5m/s

-

Max power36KW/43KW

-

Rated voltageAC 380V/50Hz

-

Pressure0.6-0.8Mpa

-

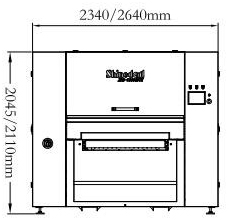

Weight6500kg/8000kg

- Grinding process

Slag hammer + Narrow sand belt + brush sand blocks

- Conveying mode

Magnetic adsorption, conveyor belt conveying

- Appearance effect

The cutting slag on the upper and lower surfaces shall be removed, and the edges of parts and holes shall be blunt

- Application

Laser plasma, flame and other cutting and blanking processes

Control system

- Siemens programmable control system

- Variable frequency drive system

- Step positioning system

- Fault alarm hint